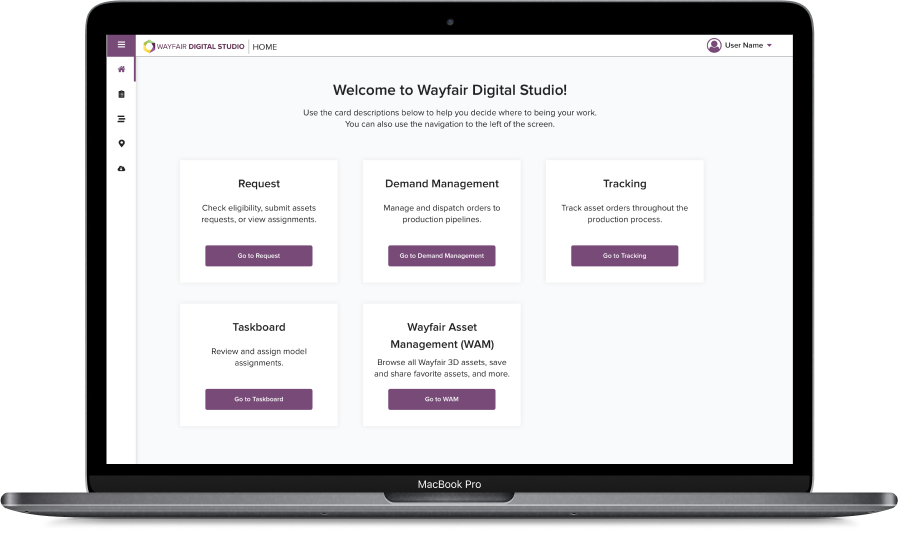

Wayfair Digital Studio

Client / Project

Wayfair

Year

2020

Role

Lead Experince Designer

Responsibilities

User Experience, UX Strategy, User Interface Design, User Research

OVERVIEW

About Wayfair

Wayfair is one of the world’s largest furniture and home décor providers. They offer more than seven million products, and connect with individual consumers, as well as small and large scale businesses. Wayfair’s primary competitor is the behemoth knowns as, Amazon.

What is Wayfair Digital Studio (WDS)?

WDS is a platform that is supposed to streamline the asset creation pipeline into one seamless flow. Wayfair has huge problem of creating internal tools that solve for a single specific use-case and this has led to some 600+ tools floating around the company. A lot of the tools have, or are on the verge of being deprecated. WDS was created with intent of making key tools work and feel connected similar to Google Suites or Adobe CC.

Wayfair Digital Studio took approximately 1.5 years from inception to developed MVP.

This project had a lot of twists and turns, and a few big company shakeups, but for the purpose of this case study I’ll stick to the highlights. Feel free to have a coffee chat with me discuss the details not detailed in this case study.

More context

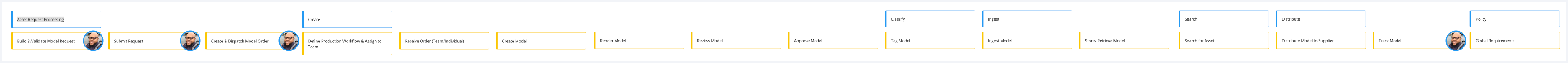

What is Asset Request Processing?

Asset Request Processing sits at the beginning of the media funnel that creates and uses 3D assets across Wayfair and partners. Asset production is the process media assets (models, imagery, videos, etc) go through prior to making it onto wayfair.com. Demand channels request assets for campaigns, catalogs, or for online inventory.

“Images sell furniture”, said someone at Wayfair.

Terms to Remember

Asset Factory (n) – where the actual production of assets is happens, “the factory”.

Asset Request (n) – the bulk submission of 1K – 10K+ types of asset production requests for a demand channel.

Demand Channel (n) – the channel that is requesting assets for example, Exclusive Brands, Speciality Retail Brand, or Catalog.

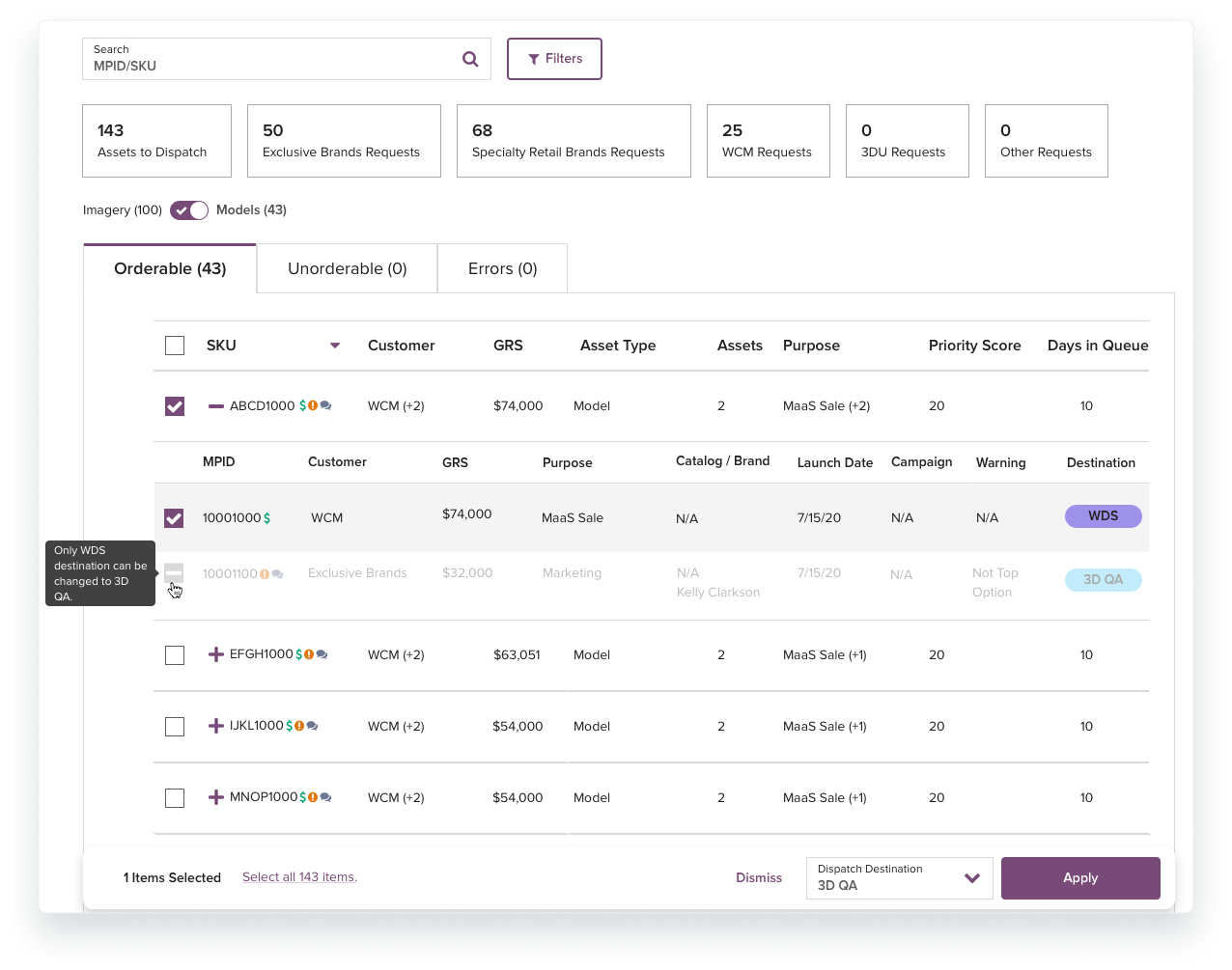

Dispatch (v) – the process of determining the production pipeline an asset order is fulfilled by post-prioritization and consolidation of overlapping orders.

Eligibility (n) – the process of identifying if a SKU / MPID is orderable or not.

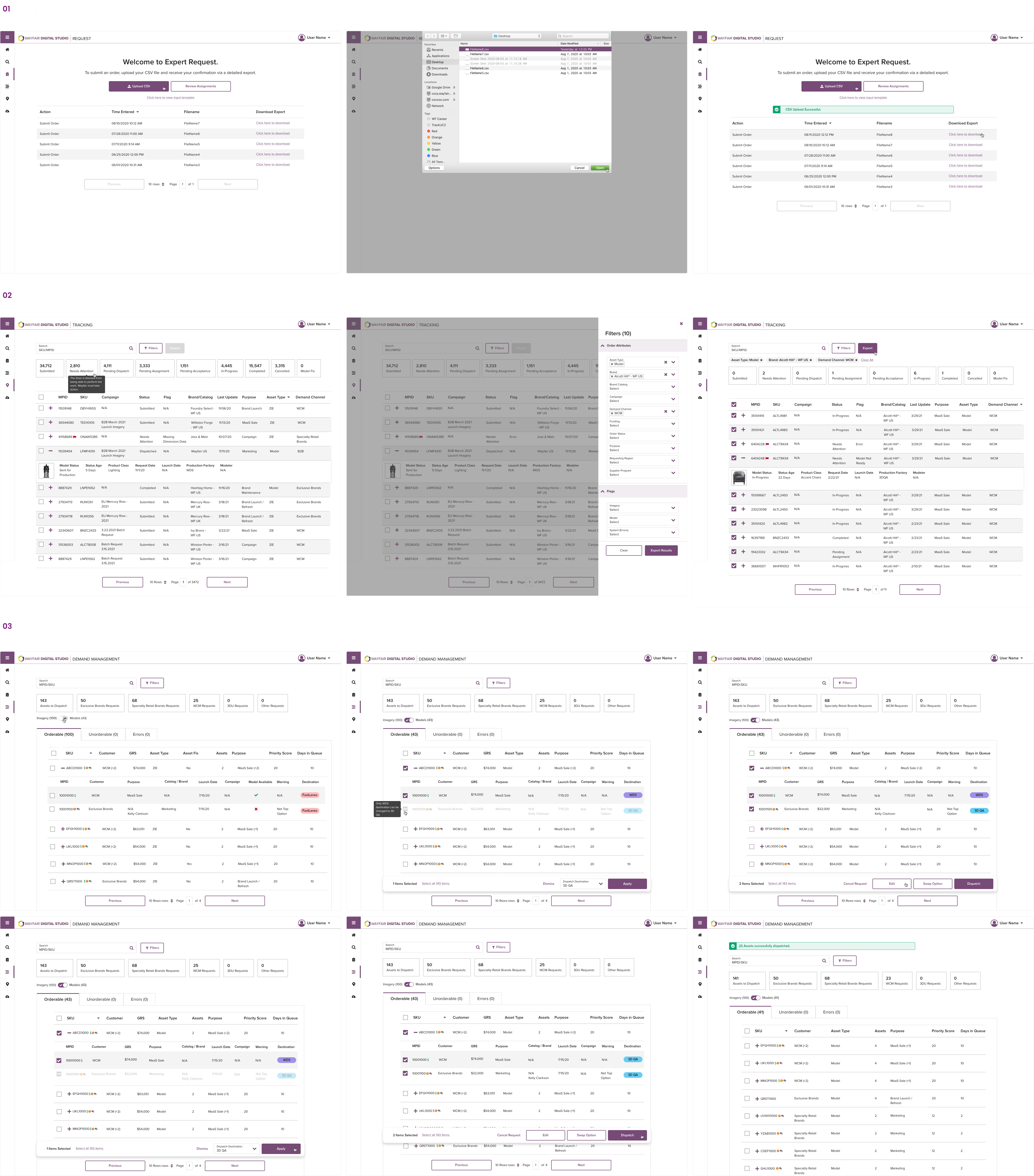

Expert Request (n) – a simple process for Demand Managers to create demand channel’s asset requests.

Imagery (n) – 2D image featuring a model in a scene that best showcases the product or multiple products.

Model (n) – 3D rendering of furniture accounting for all details from texture to material and pattern.

Problem

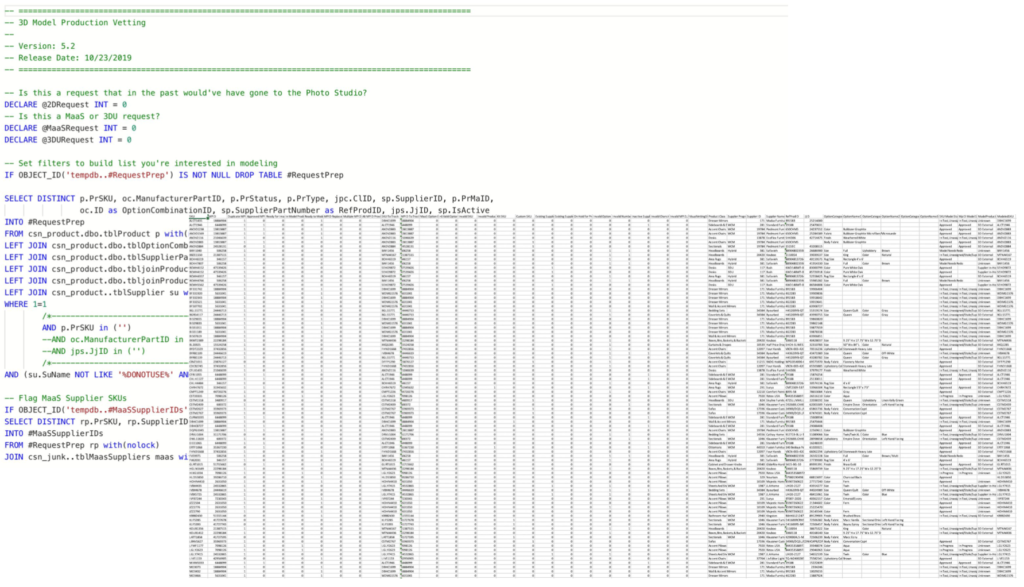

- Demand Managers manually manage the order queue (including consolidation, prioritization, and updates to the factory). The manual processes use scripts and trackers that rely on data from tables that are being deprecated in the new ecosystem.

- Tracking lives in a spreadsheet and the operations team has to run 70+ SQL scripts and dashboards to identify where an asset is in production.

goalS

Business

The Wayfair Digital Studio ecosystem should provide a seamless, tailored experience for customers and operational partners to successfully place orders and gain visibility into them, and operators to manage demand of media assets for Wayfair’s top performing products.

Asset Requesting Processing Domain

Improve a spreadsheet heavy manual process for requesting, and tracking asset into an easy to use UI with built-in prioritization logic that leans toward bulk action capabilities.

No pressure at all…

process

A Design Thinking approach was used for this project.

Empathize

- User Shadowing

- User Interviews

- User Survey

Define

- User Personas

- User Stories

Ideate

- User Flow

- HMWs

Prototype

- Wireframes

- Hi-fi Screens

Test

- Usability Test

- User Acceptance Testing

Empathize

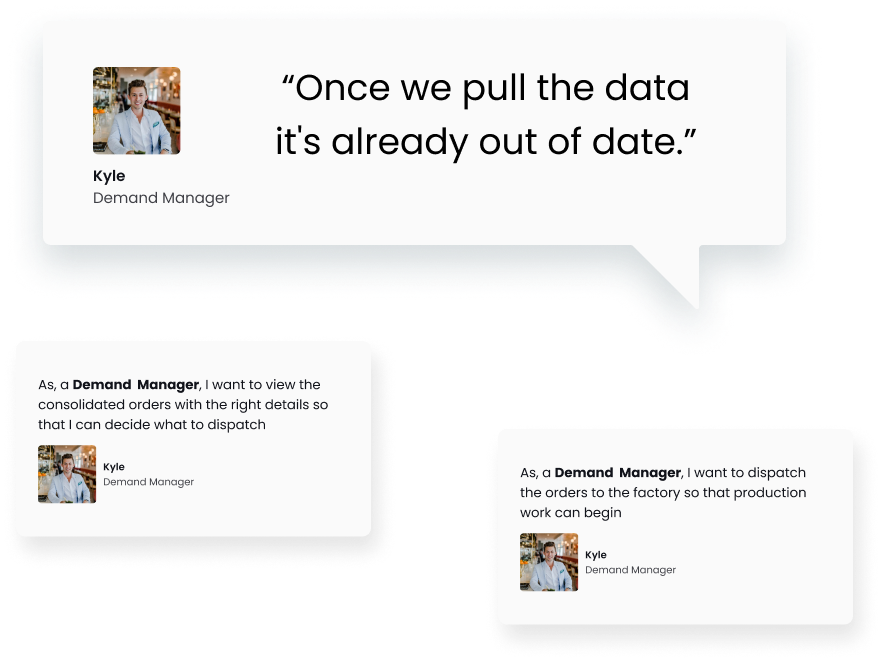

A comprehensive research process was implemented to understand stakeholder workflows and identify pain points. This included conducting interviews, reviewing past research, distributing surveys, observing daily work. A card sorting exercise was conducted to understand the decision-making process that demand managers use to prioritize orders.

Define

After extensive discussions with our product stakeholders, we identified a few key contributor roles that were essential to the asset request pipeline. All other users would be deprioritized for the MVP release.

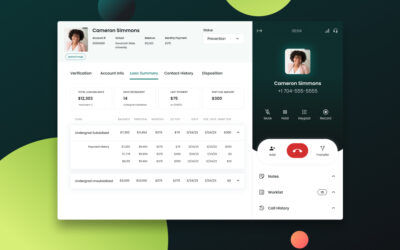

Demand Managers

We designated these users as our platform superusers. They are the only ones granted permission to access applications across all domains.

The objectives for these users involve submitting, prioritizing, consolidating, and monitoring asset orders for Demand Channels.

Demand Managers are responsible for gathering asset requests across all demand channels, using scripts and spreadsheets for object eligibility and validation, submitting requests on behalf of all demand channels, and determining the dispatch order and appropriate production pipelines for asset requests.

Demand Managers face several challenges. These include a substantial amount of manual data extraction and late discovery of an order’s eligibility for modeling. Additionally, if a product is missing images, this issue is not identified until after an order is submitted. There is also a lack of insights into overall image coverage for MPIDs.

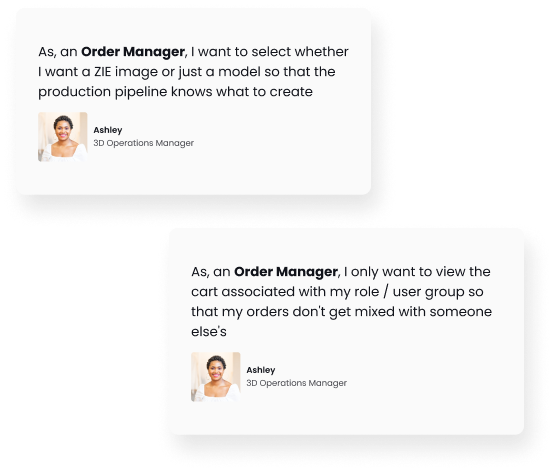

3D Ops Managers (Model & Imagery)

The objective for 3D Operations Managers is to assign and monitor the production of asset orders for demand channels.

Their tasks include planning and managing all production pipelines, prioritizing incoming requests based on demand channel and use case, and assigning these requests to production team members based on priority, complexity, and capacity. They also manage rejected assignments by either reassigning them to a new modeler or reporting back to the requester.

Challenges for 3D Operations Managers include lacking an overall view of projects at a high level, the manual and subjective prioritization of assets that consumes significant time, and the extremely time-consuming manual process of assignment routing.

Ideate

User flows were created to better understand the path from asset request to tracking. We used “How Might We” (HMWs) questions to generate initial ideas.

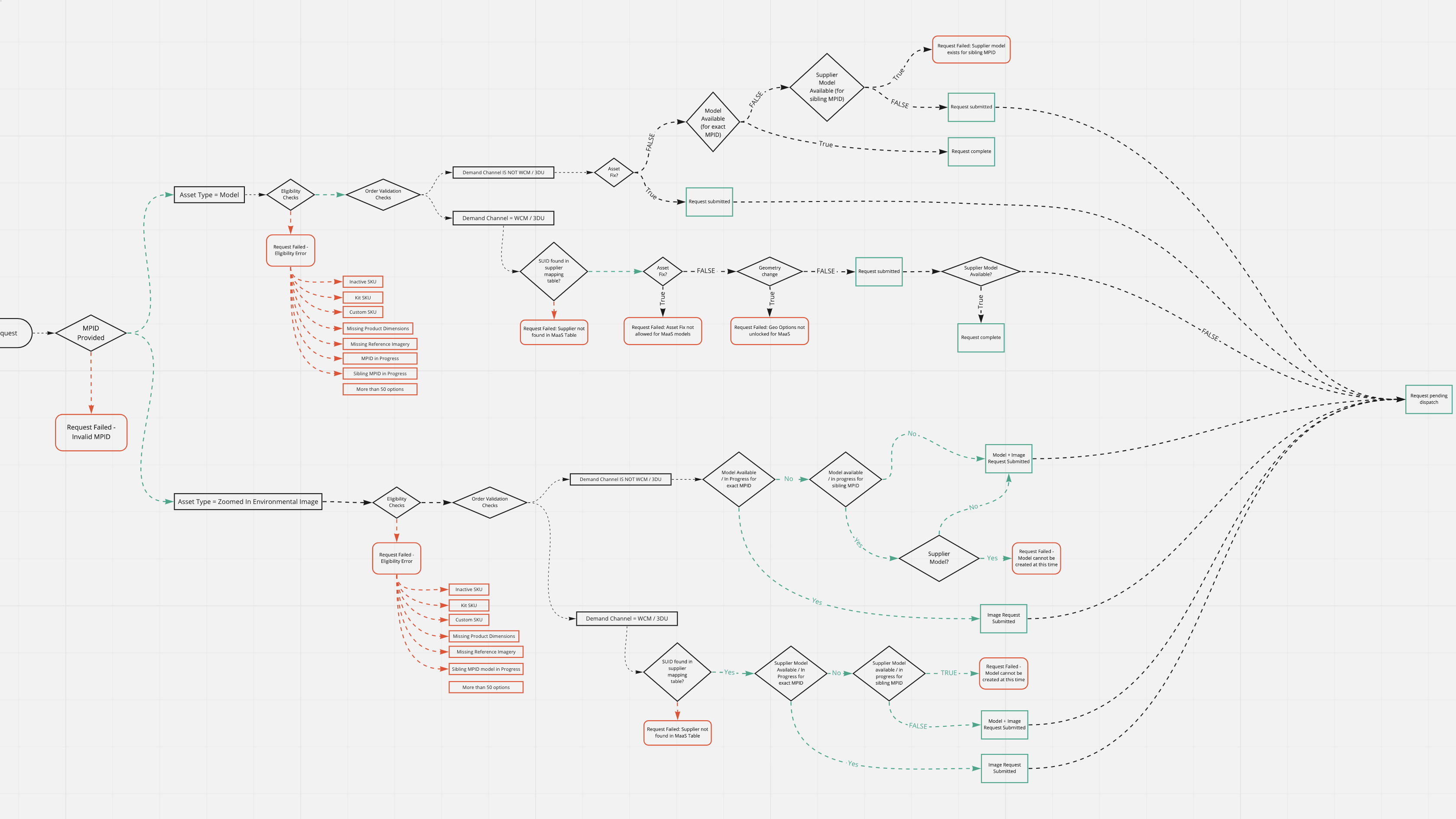

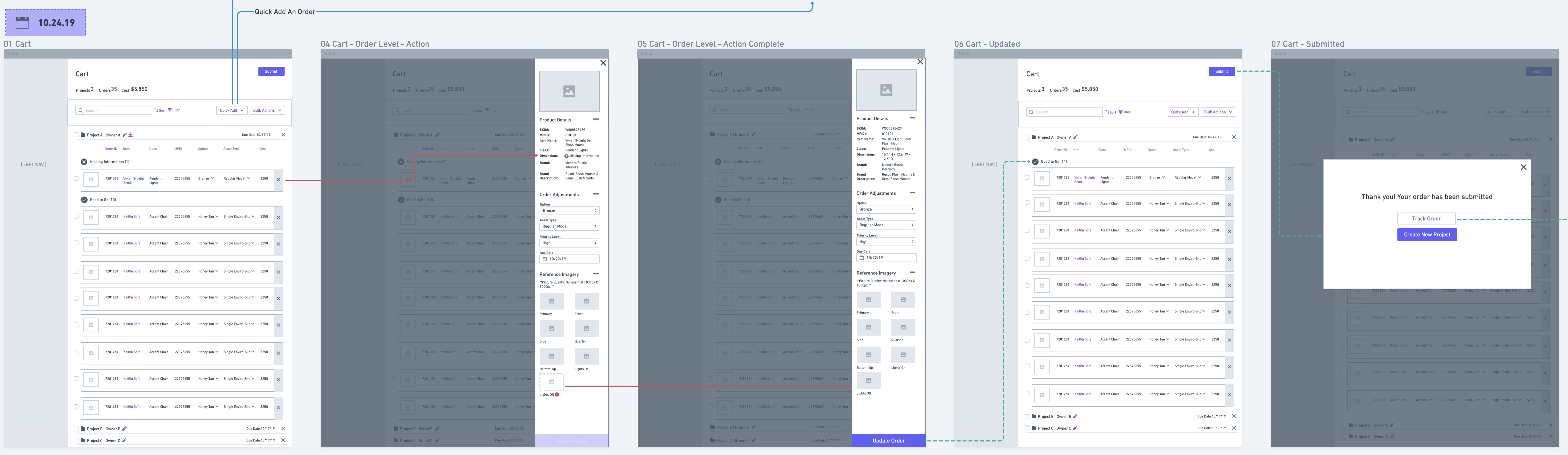

Prototype

Wireframes were created for various concepts. These concepts were presented to key stakeholders weekly for feedback.

Test

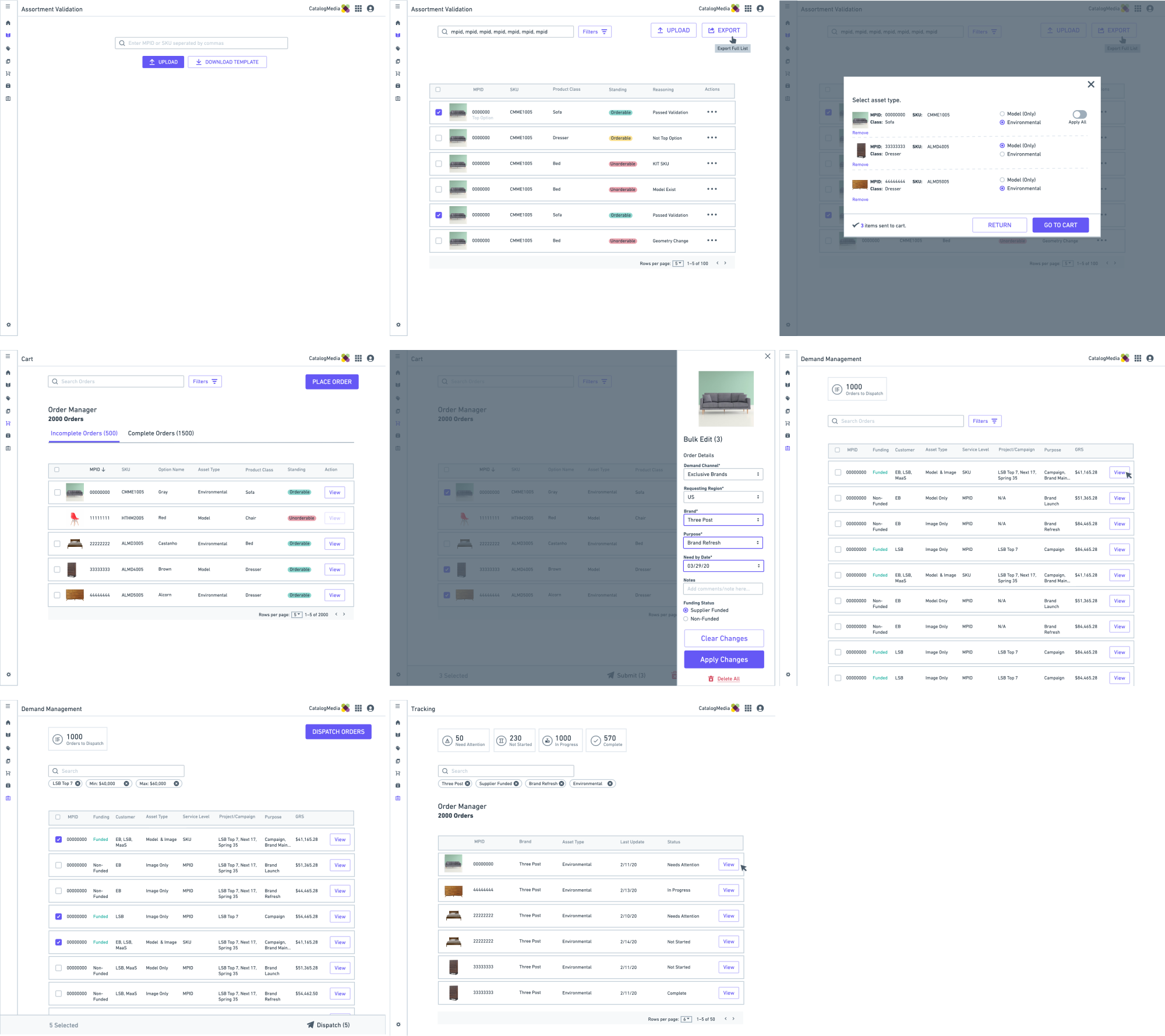

Key users were presented with a series of scenarios and tasks to complete using medium-fidelity wireframes. Their interactions were recorded through click maps, task completion time, and self-identifier questions.

A subsequent usability test was conducted using a live demo. However, the results were disappointing.

Test findings

Requesting

We had a solution that focused on creating a “shopping experience” for asset requesting processing, similar to online shopping. Once we ran a few usability tests we realized that the shopping experience approach was horribly wrong and stakeholders disliked the concept mainly because we left out key elements to stakeholder’s workflow such as, bulk actions and multiple production distribution streams.

Key Takeaway: The shopping experience concept that was pushed from higher level leadership was NOT what our stakeholders needed. Our users needed a more complex solution that accounted for the many intricacies of their job.

Tracking

There was a tracking solution that featured segmenting the tracking by demand channel. Once inside a tab tracking was organized by catalog/brand.

Key Takeaway: Our users were use to working in spreadsheets where they could see all tracking at glance, or run a SQL script to find what they needed. Users felt they had to click too much to find what they needed and didn’t like information being hidden. They needed a solution that was similar to what they were use to doing.

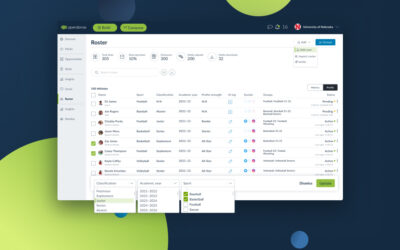

Hi-Fi Screens

Results

In the first six months of release…

Demand Managers were able to assign models to either 3DQA or WDS with one click, saving 50 hours of operational time each week.

Launched a UI service that verifies a product’s eligibility for 3D modeling. This service enhanced visibility into Catalog Eligibility, replaced outdated Production Vetting SQL Script, and reduced rejections due to issues with reference imagery and dimensions.

Hours of operational time saved each week

%

Reduction in MPID eligibility issues

%

Reduction in SKU eligibility issues

%